The Wonders of Wool: The Technical Makeup of Wool Fibres

Wool is one of nature’s most impressive creations—a fibre that’s been keeping us warm, dry, and comfortable for centuries. It’s not just its softness or cosiness that makes wool special; it’s the unique technical structure of each fibre that gives it such amazing qualities.

In this article, we’ll take a closer look at what makes wool tick, exploring the structure of wool fibres and the clever ways they work to regulate temperature, wick away moisture, and resist allergens.

A Brief History of Wool

Wool has been an integral part of human history for over 10,000 years, with its origins tracing back to the domestication of sheep in Mesopotamia. Early civilisations valued wool for its warmth, durability, and versatility, making it a staple material for clothing and trade.

By around 4,000 BCE, techniques for spinning and weaving wool had developed in the Middle East and Central Asia. Ancient Egyptians prized wool for its insulating properties, although linen often took precedence in their warm climate. In colder regions, wool quickly became the material of choice for clothing and textiles, providing essential protection against harsh weather.

The Role of Wool in Bedding

Though primarily used for garments in its early history, wool also found its way into bedding. As early as the Bronze Age (around 3,000 BCE), wool was used to create simple blankets and mats, particularly in colder climates where its insulating properties were invaluable. By the Middle Ages, wool-filled mattresses and blankets became common among wealthier households in Europe. These early uses highlighted wool’s ability to regulate temperature and resist dampness.

Wool and the Growth of Trade

During the Middle Ages, wool became the backbone of the European economy, particularly in England. Known for producing some of the finest fleece, English wool was exported across Europe and beyond. Wool’s economic significance even influenced politics; the "woolsack" in the British House of Lords remains a symbol of the industry’s impact.

Modern Wool and Its Sustainability

The Industrial Revolution transformed wool production, introducing machinery that made processing faster and more efficient. Wool’s use diversified, with innovations improving its softness and versatility for both clothing and home textiles.

Today, wool continues to be celebrated for its natural performance and sustainability.

The Technical Makeup of Wool Fibres

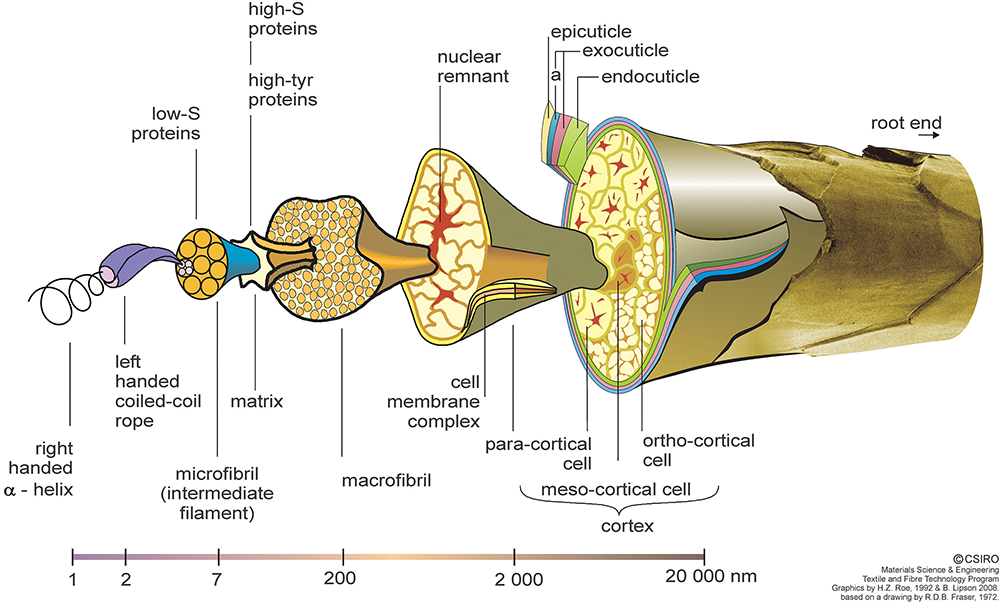

Wool’s extraordinary properties stem from its unique fibre structure, which is unlike any other natural or synthetic material. Each wool fibre is a complex combination of layers, designed by nature to provide protection, insulation, and flexibility.

Image credit: CSIRO, CC BY 3.0 via Wikimedia Commons

The Layers of Wool Fibres

Cuticle (Outer Layer):

The cuticle consists of overlapping scales, which give wool its durability and resilience. These scales repel water while allowing the fibre to absorb moisture vapor, making wool naturally moisture-wicking and resistant to mould.

This property keeps bedding dry and comfortable, even in humid conditions.

Cortex (Inner Layer):

The cortex makes up most of the wool fibre and is composed of two types of cells: orthocortical and paracortical. These cells expand and contract differently, giving wool its natural crimp or curl.

The crimp traps air, providing insulation and giving wool its lightweight, lofty feel—perfect for duvets and pillows.

Macrofibril:

Within the cortical cells are macrofibrils, which are bundles of tightly packed filaments. These macrofibrils provide structural integrity to the fibre, ensuring its strength and elasticity.

Matrix:

The matrix surrounds the macrofibrils and acts as a flexible glue, holding everything together. It is composed of proteins and plays a crucial role in absorbing moisture.

Twisted Molecular Chains and Helical Coils:

At the microscopic level, wool fibres are built from twisted molecular chains and helical coils of keratin protein. Working much like springs, this structure gives wool its remarkable elasticity and resilience, helping it to stretch and return to its original shape.

Additional Properties of Wool

Lanolin (Natural Grease):

Wool fibres are coated with lanolin, a natural, waxy substance that acts as a protective barrier against moisture and pests. Though much of the lanolin is removed during processing, enough remains to enhance wool's anti-static and hypoallergenic properties, helping it resist dust mites and allergens.

Hygroscopic Nature (Moisture Absorption):

Wool is highly hygroscopic, meaning it can absorb and release moisture without feeling damp. It can absorb up to 30% of its weight in moisture, drawing moisture away from the body and releasing it into the air. This ability helps regulate body temperature and keeps wool bedding comfortable in varying conditions.

Keratin (Protein Structure):

At the core of wool fibres is keratin, a strong, durable protein also found in human hair and nails. Keratin gives wool its strength and elasticity, allowing it to resist wear while maintaining flexibility. This molecular structure helps wool fibres return to their original shape after compression, which is particularly useful for maintaining the loft and comfort of wool-filled bedding.

The Wool Processing Journey: From Sheep to Fabric

Wool undergoes a detailed process before becoming the high-quality material used in products like bedding and clothing.

1. Shearing:

Wool is carefully harvested from sheep around spring time, with breeds selected for their fine wool. Baavet sources 100% British wool from sheep suited to the temperate climate, ensuring ethical, sustainable practices.

2. Cleaning:

After shearing, the wool is washed in a series of water baths to remove dirt, grease, and lanolin.

We pride ourselves on using a chemical-free cleaning process that preserves wool’s natural properties.

3. Carding:

In this stage, wool fibres are combed and aligned into soft, uniform strands. This step is crucial for spinning yarns, creating felt, or layering for products like duvets and pillows.

Here at Baavet we ensure the wool is carded multiple times to achieve a consistent loft.

4. Blending (omitted for Baavet bedding):

For some applications, wool is blended with other fibres like cotton or synthetic materials to alter texture, durability, or elasticity.

We don’t blend our wool - it’s 100% pure natural wool to maintain its natural breathability.

5. Dyeing (omitted for Baavet bedding):

If the wool is destined for colourful textiles, it is dyed either before or after spinning into yarn. This step allows for a vast range of design possibilities in fashion and home decor but is usually skipped for natural wool bedding to retain its purity.

6. Spinning (omitted for Baavet bedding):

The fibres are twisted into yarns of varying thicknesses and strengths, ready for weaving or knitting into fabrics. For non-woven applications like felts, this step is omitted.

7. Weaving or Felting (omitted for Baavet bedding):

Spun yarns are woven into fabrics for clothing, blankets, or upholstery. Alternatively, wool can be compressed into felt, which is commonly used in crafts, hats, and industrial products.

8. Finishing:

The final stage of wool processing varies based on the intended product. For textiles, treatments like fulling (a controlled shrinking process) or napping (brushing the surface for softness) may be applied to enhance durability, texture, or appearance. Wool used in upholstery or industrial applications might undergo treatments for stain resistance or flame retardancy.

In the case of bedding, finishing involves layering the wool into even sheets and encasing in high-quality cotton. Baavet uses 100% cotton to complement wool’s natural properties, ensuring durability, breathability, and softness without the use of synthetic materials.

The Timeless Appeal of Wool

Wool’s extraordinary composition and properties have cemented its place as one of the most versatile natural materials in history. From its layered structure—designed to offer resilience, moisture management, and insulation—to its hypoallergenic and sustainable qualities, wool continues to adapt to modern needs while remaining deeply rooted in tradition.

Whether transformed into luxurious textiles, protective outerwear, or breathable bedding, wool’s ability to regulate temperature, resist fire, and endure wear makes it an unparalleled choice across industries. At Baavet, we take these age-old benefits a step further by selecting and processing wool with meticulous care, ensuring it meets the highest standards of comfort and performance.

As a renewable, biodegradable resource, wool not only supports sustainable practices but also provides solutions for a healthier and more comfortable lifestyle. Its natural brilliance, honed over centuries, reminds us of the enduring power of nature’s finest materials.

Ready to experience the benefits of wool for yourself? Browse our range of high-quality wool bedding and discover how it can transform your sleep.